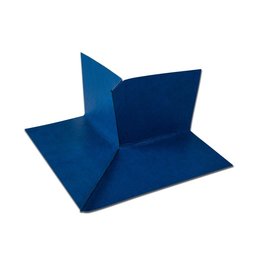

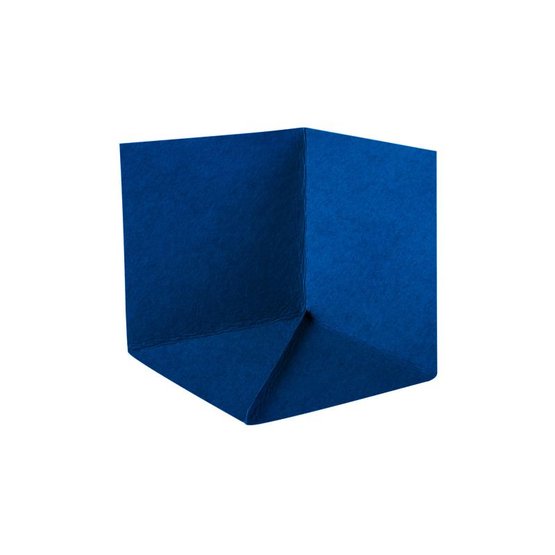

Homogeneously weldable shaped element for interior corners

Advantages

- Simple implementation of vulnerable joints thanks to pre-fabrication

- Reliable sealing of corners: homogeneously weldable with a solvent welding agent or hot air

- Extremely high tear-resistance and very stable

- Can be easily adapted for shorter base lengths, for example, using a knife or scissors

- High degree of occupational safety: non-slip and abrasion-resistant surface

Areas of application

For reliable installation of joints at interior corners within the SOLITEX WELDANO roofing underlay system. The permeable shaped element, which is supplied pre-welded, can be welded to the SOLITEX WELDANO 3000 roofing underlay membrane in a homogeneous manner in terms of materials using the system solvent welding agent or hot air.