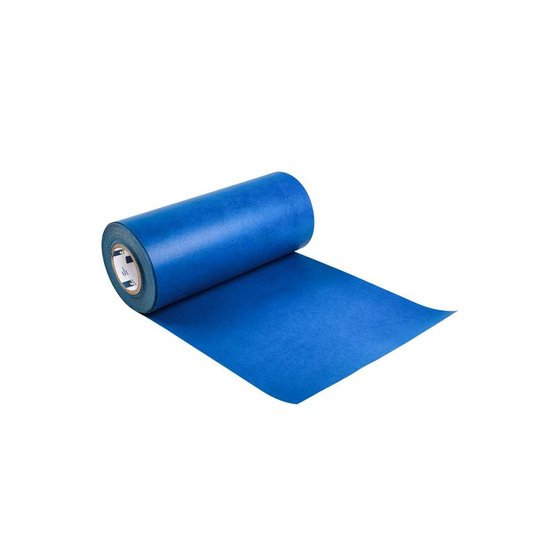

Diffusion-open, weldable roofing underlay membrane strips

Advantages

- Reliable seam sealing: homogeneously weldable as part of the SOLITEX WELDANO 3000 system

- Can be used flexibly: also suitable for large counter battens

- Easy to work with: robust with extremely high tear-resistance

- Maximum protection: diffusion-open, rainproof against driving rain, and highest hail-resistance HR 5 (Swiss VKF/AEAI directive) and as per EN 13583

- Can be easily cut to shape using a knife or scissors

Areas of application

For reliable sealing around counter battens as part of the SOLITEX WELDANO 3000 system.

Installation instructions

Substrate

Before welding is carried out, SOLITEX WELDANO should be wiped clean with a cloth. Welding is not possible on frozen membranes. There must be no water-repellent substances (e.g. grease or silicone) on the membranes. Subsurfaces must be sufficiently dry and stable. It is recommended that spot checks be performed to test the strength of the welded joints.

General conditions

SOLITEX WELDANO 3000 is to be installed horizontally (parallel to the eave). Unhindered drainage of water must be ensured. Cross joints are to be avoided. If membrane joints are necessary, they should be offset with respect to each other.

When used to protect building structures during the construction phase, SOLITEX WELDANO 3000 roofing underlay membranes can be subjected to outdoor exposure for up to 6 months in Central and Northern Europe and in Canada and the northern United States, and up to 4 months in Southern Europe, the rest of the United States and the rest of the world – e.g. as a temporary covering in accordance with the German ZVDH regulations. The roof pitch must be at least 3°. National regulations should be taken into account here.

Fasteners may not be applied on flat surface areas or in areas where water run-off is collected (e.g. in roof valleys). We recommend the use of corrosion-resistant fasteners.

The membrane edges are to be welded using the WELDANO TURGA (HS) system solvent welding agent or a hot air gun. The welding area must be dry and free of frost, dust and grease. If there is dirt (e.g. oil) on the surface, moisten a cloth lightly with WELDANO TURGA (HS) system solvent welding agent and use it to clean off this dirt. Both sides of the membrane can be welded and are suitable as upper layers. Welding with a solvent welding agent can be carried out at temperatures above 0 °C / 32 °F. Please observe the hazard notices on the container.

If a hot air gun is being used, we recommend a temperature of around 220 to 280 °C (430 to 530 °F) depending on the ambient temperature and wind conditions. Test this setting by carrying out a test weld on a sample piece of membrane. A 40 mm (1.6″) nozzle width has been found to be suitable in practice for welded joints between surface membranes. A 20 mm (¾″) nozzle may be more suitable in certain cases for more intricate joints.

Note: If membranes that have been subjected to 2 months of outdoor exposure are to be welded, the exposed membrane surface must be gently roughened using sandpaper (150 - 250 grade) to remove a film depth of around 2-3 μm (0.08-0.12 mil) so that a reactive surface is accessible again. This applies both for hot-air welding and for solvent welding using WELDANO TURGA (HS).

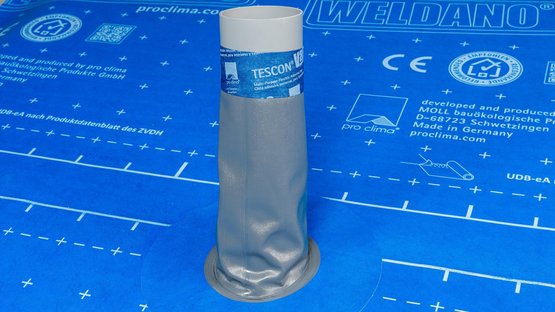

The WELDANO ROFLEX MODI pipe grommets are suitable for pipe diameters from 30 mm to 360 mm (1³⁄₁₆″-14³⁄₁₆″) for roof pitches greater than 5° (1:12).

As an alternative to the use of the WELDANO ROFLEX, WELDANO INVEX or WELDANO INCAV system shaped elements, these elements can also be made by cutting appropriate shapes out of SOLITEX WELDANO 3000 membranes.

Important: The enclosed counter battens on the waterproof roofing underlay must be dry and chamfered on their upper side (≥ 3 mm; 120 mils) when they are installed. Ideally, structural timber should be used.

Additional technical information for Germany:

Depending on the requirements demanded of the roofing underlay when used as an additional measure, the roofing underlay can be installed to be rainproof or watertight (in accordance with ZVDH).

Rainproof roofing underlay: The counter battens are installed over the roofing underlay membrane.

Waterproof roofing underlay: The counter battens are integrated into the sealing layer. The roofing underlay membrane is installed over the counter battens here or else SOLITEX WELDANO-S 3000 sealing strips are fitted over the counter battens and welded to the roofing underlay membrane on both sides.

Ridge ventilation is permitted in the case of a rainproof roofing underlay. The roofing underlay membrane should then stop 30 mm (1.2″) before the apex of the ridge. Cover the ventilation opening with a membrane strip over the counter batten along the ridge axis. Ridge ventilation is not permitted in the case of a waterproof roofing underlay.

The SOLITEX WELDANO 3000 roofing underlay membrane is to be sealed in a windproof and waterproof manner at the eave flashing. The eave flashing can be installed as a drip board under the gutter or as a guide board that guides water into the gutters. To protect the roofing underlay membrane from direct sunlight on a permanent basis, the width of the eave flashing should be selected appropriately depending on the roof pitch and the orientation of the building structure.

Additional technical information for Switzerland:

In the case of higher loads (e.g. pitch less than 10°), additional protection of the counter battens – for example, welding to enclose them (using SOLITEX WELDANO 3000 or SOLITEX WELDANO-S 3000 sealing strips) – is necessary.

According to SIA 232/1, a roofing underlay for exceptional loads must always be drained into gutters or onto adjacent roof areas. To protect the roofing underlay membrane from direct sunlight on a permanent basis, the width of the guide board should be selected appropriately depending on the roof pitch and orientation of the building structure. Flat roof membranes should be used in place of SOLITEX WELDANO 3000 in locations with an increased risk of trapped meltwater, ice formation or deposits of fine driven snow.

pro clima on the outside ... and it's a wrap!

Weathertightness with pro clima

Find out more about pro clima's system solutions and products for sealing your building envelope on the outside - with roofing underlay membranes, breather membranes for facades, protective membranes for timber structures during the construction phase, and a full range of sealing tapes, sealants and accessories.