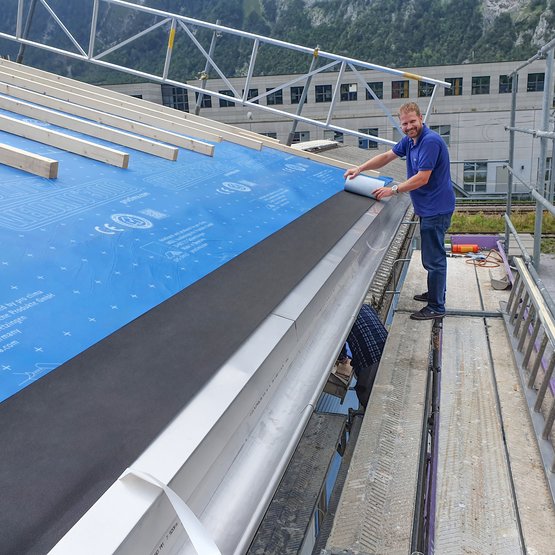

UV-resistant, full-surface adhesive membrane strip for eaves

Advantages

- Very long service life: UV ageing test carried out for 10,000 h instead of 336 h

- Long-term protection thanks to the high resistance to ageing and heat of the TEEE functional film

- Easy and reliable installation thanks to its split release film

- Sticks immediately to subsurfaces that have sufficient stability

- Flexible use: can also be used on facades

- Maximal flexibility in planning construction schedules thanks to up to 6 months of outdoor exposure during the construction phase

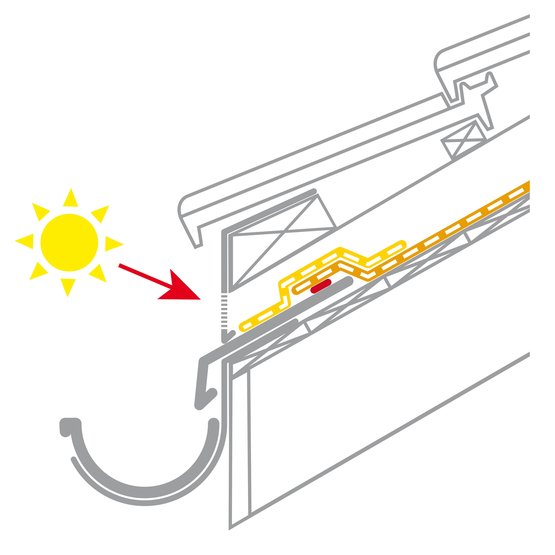

Areas of application

Eave membrane for installation on SOLITEX WELDANO for open eave ends with a perforated plate. Allows for drainage of the roofing underlay into the gutters.

Splits on release film

| Strip width | Split (approx.) |

|---|---|

| 280 mm (11″) | 30 | 250 mm (1³⁄₁₆″ | 9¹³⁄₁₆″) |

Technical specs

| Material | |||

| Fleece | Polypropylene microfibre | ||

| Functional film | Monolithic TEEE | ||

| Fleece | Polypropylene microfibre | ||

| Functional film | Monolithic TEEE | ||

| Fleece | Polypropylene microfibre | ||

| Adhesive | Special acrylate adhesive | ||

| Release film | Silicone-coated PE film | ||

| Property | Regulation | Value | Regulation |

| Colour | Black | ||

| Surface weight | EN 1849-2 | 390 g/m² ; 1.28 oz/ft² | EN 1849-2 |

| Thickness | EN 1849-2 | 1.1 mm ; 43 mils | EN 1849-2 |

| Water vapour resistance factor µ | EN ISO 12572 | 185 | EN ISO 12572 |

| sd value | EN ISO 12572 | 0.2 m | EN ISO 12572 |

| g value | 1 MN·s/g | ||

| Vapour permeance | 16.4 US perms | ||

| Reaction to fire classification | EN 13501-1 | E | EN 13501-1 |

| Outdoor exposure | 6 months, permanent against diffuse UV light in the eave area | ||

| Water column | EN ISO 811 | 10 000 mm ; 32' 10" | EN ISO 811 |

| Watertightness, non-aged/aged* | EN 13859-1 | W1 / W1 | EN 13859-1 |

| Tensile strength MD/CD | EN 13859-1 (A) | 480 N/5 cm / 340 N/5 cm ; 55 lb/in / 39 lb/in | EN 13859-1 (A) |

| Tensile strength MD/CD, aged* | EN 13859-1 (A) | 360 N/5 cm / 260 N/5 cm ; 41 lb/in / 30 lb/in | EN 13859-1 (A) |

| Elongation MD/CD | EN 13859-1 (A) | 60% / 70% | EN 13859-1 (A) |

| Elongation MD/CD, aged* | EN 13859-1 (A) | 45 % / 50 % | EN 13859-1 (A) |

| Nail tear-resistance MD/CD | EN 13859-1 (B) | 300 N / 380 N ; 67 lbf / 85 lbf | EN 13859-1 (B) |

| *) Durability after artificial ageing for 10,000 h of UV ageing instead of 5,000 h | EN 1297 / EN 1296 | Passed | EN 1297 / EN 1296 |

| Flexibility at low temperature | EN 1109 | ‑40 °C ; ‑40 °F | EN 1109 |

| Temperature resistance | Permanent ‑40 °C to 100 °C ; ‑40 °F to 212 °F | ||

| Thermal conductivity | 0.04 W/(m·K) | ||

| CE labelling | EN 13859-1 | Yes | EN 13859-1 |

pro clima on the outside ... and it's a wrap!

Weathertightness with pro clima

Find out more about pro clima's system solutions and products for sealing your building envelope on the outside - with roofing underlay membranes, breather membranes for facades, protective membranes for timber structures during the construction phase, and a full range of sealing tapes, sealants and accessories.