All-round hydrosafe® high-performance vapour control membrane

Advantages

- Excellent protection against mould and moisture damage to structures thanks to humidity-variable diffusion resistance

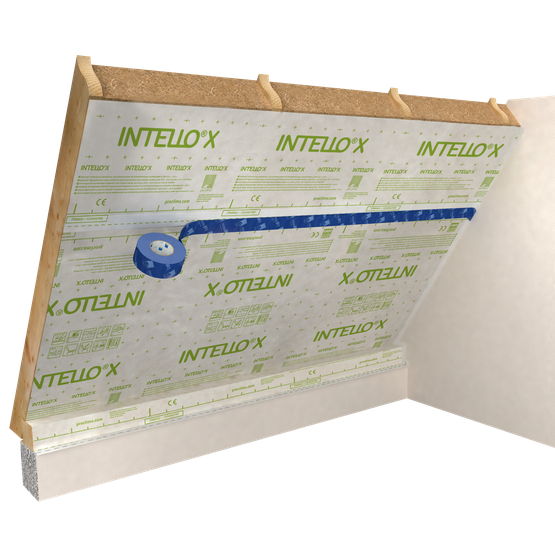

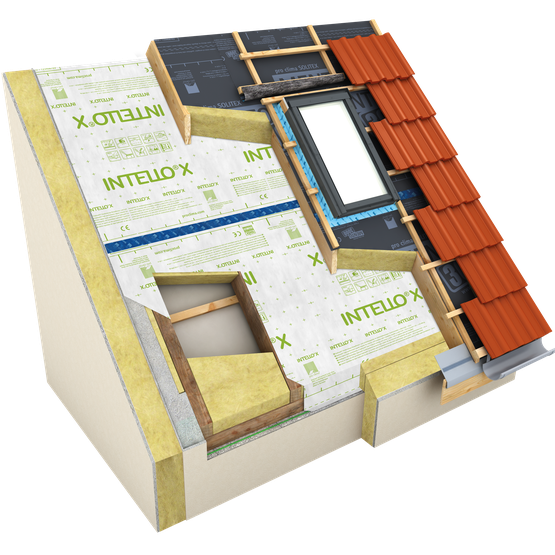

- Easier handling: can be used with insulation installed between rafters/framework, with external insulation and – in the case of refurbishment from the outside – between two layers of mineral wool insulation

- Protects building structures against weathering during the construction phase for roof pitches of 10° (2.1:12) and higher

- Protected winter building sites thanks to hydrosafe® behaviour

- Excellent values in hazardous substance testing, has been tested according to the ISO 16000 evaluation scheme

Areas of application

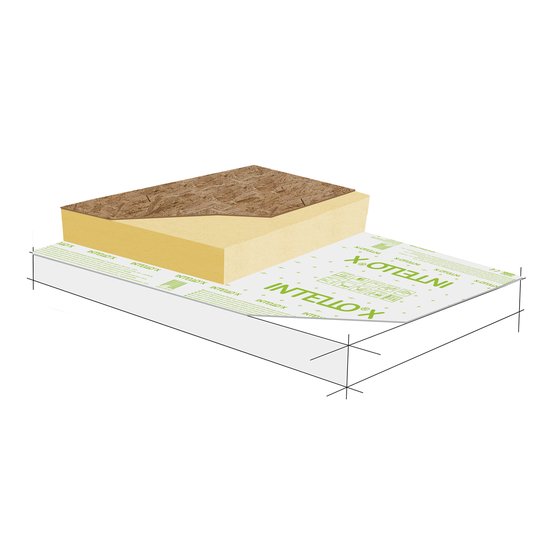

Vapour control (alternate terms: vapour check or retarder) membrane for use on the inside of insulation installed between rafters or wall framework, in combination with fibrous insulation mats and boards. Can be installed directly on top of sheathing for use underneath exterior insulation, also in combination with blown-in insulation materials.

This membrane can be permanently exposed to diffuse UV light – e.g. in areas without inner cladding.

In the case of refurbishment from the outside and installation between two layers of insulation, the choice of insulation materials for the two layers is limited to mineral or rock wool. The thickness of the external mineral wool insulation needs to be calculated on a project-specific basis; please contact Technical Support at pro clima in Germany for assistance.

This membrane can be used on building structures that are diffusion-open to the outside or are diffusion-tight, e.g. pitched, flat or green roofs, after appropriate design calculations have been carried out.

Technical specs

| Material | |||

| Protective and covering fleece | Polypropylene | ||

| Functional film | Polyethylene copolymer | ||

| Property | Regulation | Value | Regulation |

| Colour | Light grey | ||

| Surface weight | EN 1849-2 | 130 g/m² ; 0.43 oz/ft² | EN 1849-2 |

| Thickness | EN 1849-2 | 0.45 mm ; 18 mils | EN 1849-2 |

| Water vapour resistance factor µ | EN 1931 | 31 100 | EN 1931 |

| sd value | EN 1931 | 14 m | EN 1931 |

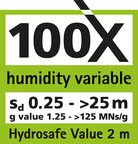

| sd value, humidity-variable | EN ISO 12572 | 0.25 ‑ >25 m | EN ISO 12572 |

| g value | 70 MN·s/g | ||

| g value, humidity-variable | 1.25 ‑ >125 MN·s/g | ||

| Vapour permeance | ASTM E96-A | 0.23 perms | ASTM E96-A |

| Vapour permeance, humidity-variable | EN ISO 12572 | < 0.13 ‑ 13 perms | EN ISO 12572 |

| Hydrosafe value (sd) | DIN 68800-2 | 2 m | DIN 68800-2 |

| Surface burning characteristics | ASTM E84 | Class A (Flame Spread 0; Smoke development index 105) | ASTM E84 |

| Fire class | EN 13501-1 | E | EN 13501-1 |

| Outdoor exposure | 2 months | ||

| Outdoor exposure for refurbishment betw. 2 insulation layers | 14 days ; 7 days at ≤10 °C (≤50 °F) | ||

| UV resistance | Can be permanently exposed to diffuse UV light | ||

| Watertight joints with ‘connect’ adhesive strips or TESCON tape | EN 13859-1 | W1 | EN 13859-1 |

| Watertightness to liquid water | EN 1928 | W1 | EN 1928 |

| Water column | EN ISO 811 | > 2 500 mm ; > 8' 2" | EN ISO 811 |

| Tensile strength MD/CD | EN 12311-2 | 250 N/5 cm / 170 N/5 cm ; 29 lb/in / 19 lb/in | EN 12311-2 |

| Elongation MD/CD | EN 12311-2 | 60% / 60% | EN 12311-2 |

| Nail tear resistance MD/CD | EN 12310-1 | 120 N / 120 N ; 27 lbf / 27 lbf | EN 12310-1 |

| Durability after artificial ageing | EN 1296 | Passed | EN 1296 |

| Temperature resistance | EN 1109, EN 1296, EN 1297 | Permanent ‑40 °C to 80 °C ; ‑40 °F to 176 °F | EN 1109, EN 1296, EN 1297 |

| Thermal conductivity | 0.04 W/(m·K) ; 0.3 BTU·in/(h·ft²·°F) | ||

| Passive House Certification | Passivhaus Institut | phA | Passivhaus Institut |

| CE labelling | EN 13984 | Yes | EN 13984 |