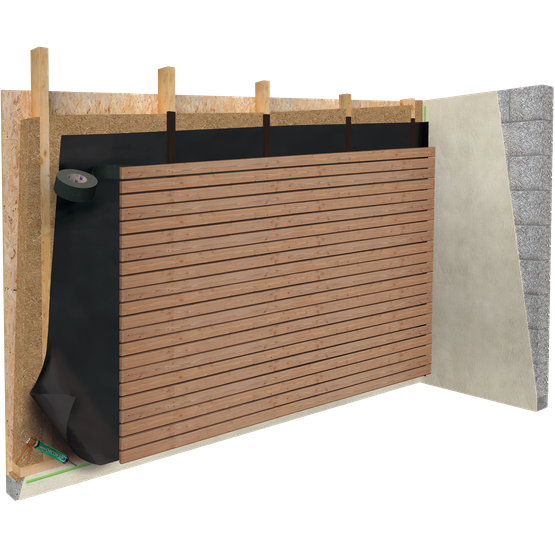

Breather membrane (WRB) for open-jointed cladding, gap width up to 35 mm (1⅜″)

Advantages

- Well-protected building structures: highly permeable and, at the same time, maximum protection against driving rain

- Dry building structures: pore-free TEEE functional film actively transports moisture to the outside

- Not visible behind open-jointed cladding: black fleece with printed marking only in the overlap area

- Highest possible durability and thermostability thanks to the TEEE functional film

- 6 months of outdoor exposure

Areas of application

For use as a breather membrane (weather-resistive barrier, WRB) behind closed and open facades (open-jointed cladding up to a gap width of 35 mm (1⅜″); cladding width = at least 3 x gap width). Installation onto boarding, wood-based panels and all mat or panel-shaped thermal insulation materials.

Exterior wind sealing – Best possible protection for rainscreen facades

Windproofing with active moisture management

SOLITEX FRONTA QUATTRO breather membranes (WRBs) are equipped with state-of-the-art non-porous, monolithic polymer membranes that actively manage moisture. They offer significantly higher levels of structural protection compared with conventional, microporous membranes.

Setting new standards: monolithic SOLITEX membrane

SOLITEX FRONTA QUATTRO has a non-porous, monolithic polymer membrane, which provides excellent protection against driving rain. Compared to conventional breather membranes (WRBs) in which permeability is achieved via air exchange through the microporous membrane, a SOLITEX membrane enables active diffusion along the molecular chains.

At the same time, SOLITEX FRONTA QUATTRO has a sd value of 0.05 m, a g value of 0.25 MNs/g and vapour permeance of 66 US perms. Its active moisture transportation makes the monolithic polymer membrane extremely quick drying, which optimally protects against ice forming on the membrane in winter. If ice should form, permeable breather membranes (WRBs) turn into vapour barriers (ice is impermeable) and then become moisture traps.

Additional features of the monolithic polymer membrane are the reliable protection against substances that impregnate wood (drops of water cannot penetrate the membrane even at reduced surface tension because there are no pores) and the particularly high thermal stability (melting point polymer about 200 °C (390 °F), PP about 140 °C (280 °F)). This thermal stability gives the plastic its extremely high ageing stability.

Top performance for all requirements

The functional film is reliably protected between two robust, particularly tear-resistant protective and covering fleeces made of polypropylene – ideal if there are high stresses when laying the membranes.

- The covering fleece is also water repellent and provides optimum protection against penetrating water. It protects the underlying specialist film from damage and UV radiation.

- As a result of the black colour of the outer covering fleece, the membranes are anti-glare.

- The membrane can be exposed to the elements for up to 6 months.