Diffusion-open, weldable roofing underlay membrane

Advantages

- Reliable seam sealing: homogeneously weldable

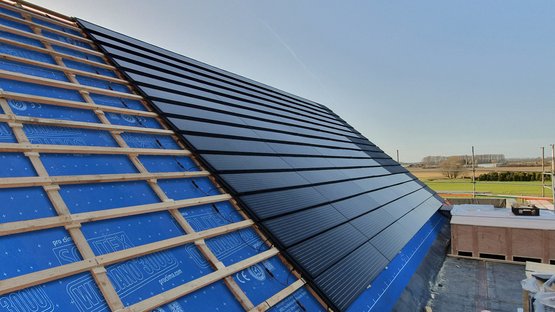

- Suitable for use under roof-integrated solar panels

- Excellent occupational safety: non-slip and abrasion-resistant surface

- Suitable as a roofing underlay to meet the most stringent requirements

- Maximum protection: diffusion-open, rainproof against driving rain, and highest hail-resistance HR 5 (Swiss VKF/AEAI directive) and as per EN 13583

- Easy to work with: robust with extremely high tear-resistance

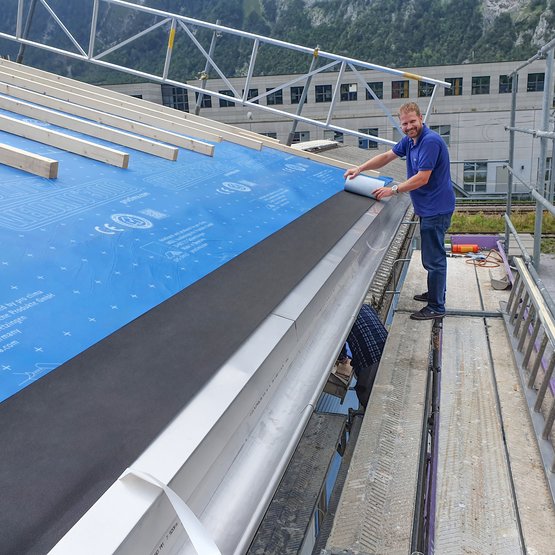

- Also keeps structural elements dry during the construction phase: excellent protection against driving rain thanks to monolithic functional film

- Cutting and welding service available for SOLITEX WELDANO 3000

Areas of application

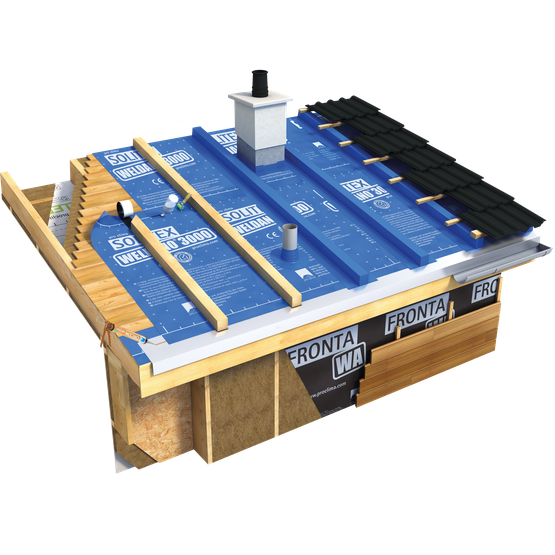

For use as a 3-ply diffusion-open, homogeneously weldable, rainproof/watertight roofing underlay membrane. Suitable for installation over pressure-resistant subsurfaces, e.g. timber sheathing, wood-based panels and wood-fibre underlay panels. Particularly suitable for use underneath roof-integrated solar panels.

Planning and construction guidelines

The difference between rainproof and waterproof sub-roofs

Sub-roofs serve as an independent sealing layer underneath the actual roof covering. They are installed as an additional measure to ensure either rainproofing or waterproofing of covered roof structures if the roof pitch is less than the standard roof pitch. Sub-roofs are installed on a subsurface with sufficient load-bearing capacity, e.g. on even sheathing consisting of solid wood or wood-based panels with a pressure resistance of ≥100 kPa (≥14.5 psi) at 10% strain and/or a surface layer with a density of ≥150 kg/m³ (≥ 9.4 lb/ft³).

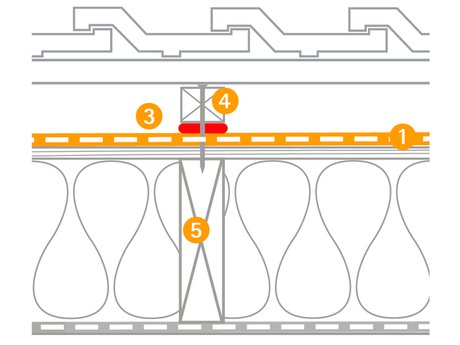

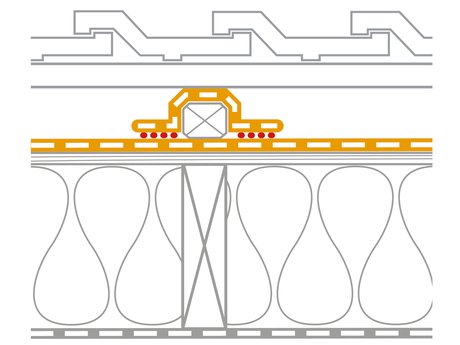

There are two different sealing solutions (see Fig. 1 and Fig. 2) available from pro clima to seal the penetrations caused by nails or screws to ensure that the SOLITEX WELDANO sub-roof system is waterproof: the TESCON NAIDECK mono nail-sealing tape for moderate rain loads, and covering of the counter battens with SOLITEX WELDANO-S 3000 welded strips for high loads. Covering of the counter battens with welded joints is recommended for roof pitches below 10° (2.1:12) to protect the roof structure against penetrating water. Any applicable national or local regulations and standards should be taken into account here. The main difference between these two sealing solutions relates to the position of the counter battens relative to the sealing layer. If a nail-sealing tape is used, the counter battens are installed above the rainproof layer (see Fig. 1).

Any precipitation water that enters must also be drained off in a reliable manner around the counter battens. In the SOLITEX WELDANO 3000 system, this is achieved by installing TESCON NAIDECK mono nail-sealing tape beneath the counter battens.

Fig. 1: Rainproof sub-roof: Counter batten with nail-sealing tape on the seal membrane (Switzerland: standard design for exceptional loads)

In the case of waterproof sub-roofs, the counter battens are also integrated into the sealing, e.g. by installing the surface roofing underlay membrane over the counter battens. With regard to installation, however, it is often easier to first install the membrane flat on the sheathing, and then to fasten the counter battens and weld a SOLITEX WELDANO-S 3000 sealing strip over them, see Fig. 2.

Important: The counter battens must be dry and chamfered on their upper side (≥ 3 mm (⅛″)) when they are installed. Ideally, kiln-dried battens should be used.

When SOLITEX WELDANO-S 3000 strips are used, the number of attachment nails or screws used to attach the horizontal roof battens should be kept to a minimum. The number of penetrations should also be kept to the minimum necessary. The joints with the penetrating components must then be sealed/welded at a sufficient height above the sub-roof underlay membrane in a waterproof manner, in accordance with the regulations.

Openings in the ridge area are not permitted on waterproof sub-roofs. In contrast, openings in the ridge area can be included on rainproof sub-roof if an appropriate design structure is implemented.

Rainproof and waterproof sub-roof can be implemented in a practical, reliable manner using the SOLITEX WELDANO 3000 system.

Fig. 2: Waterproof sub-roof: Counter batten integrated into the sealing layer (Switzerland: possible additional measure)

Technical support

If you have questions relating to planning and installation, please contact pro clima Technical Support.

pro clima on the outside ... and it's a wrap!

Weathertightness with pro clima

Find out more about pro clima's system solutions and products for sealing your building envelope on the outside - with roofing underlay membranes, breather membranes for facades, protective membranes for timber structures during the construction phase, and a full range of sealing tapes, sealants and accessories.