Airtightness membrane for roof refurbishment from the outside, with self-adhesive strips

Advantages

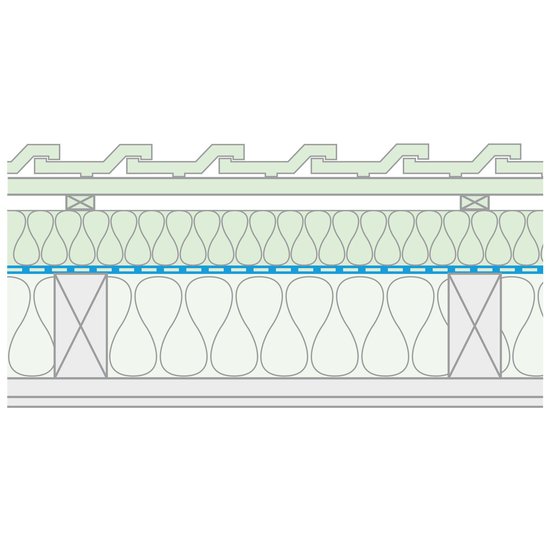

- Simple implementation of the airtightness layer: installation across rafters and insulation

- Dry and well-protected building structures thanks to active moisture transport

- Protection during the construction phase: suitable as a temporary covering

- Quick and reliable adhesion thanks to the integrated ‘connect’ self-adhesive strips along the membrane strips

- Excellent values in hazardous substance testing, has been tested according to the ISO 16000 evaluation scheme

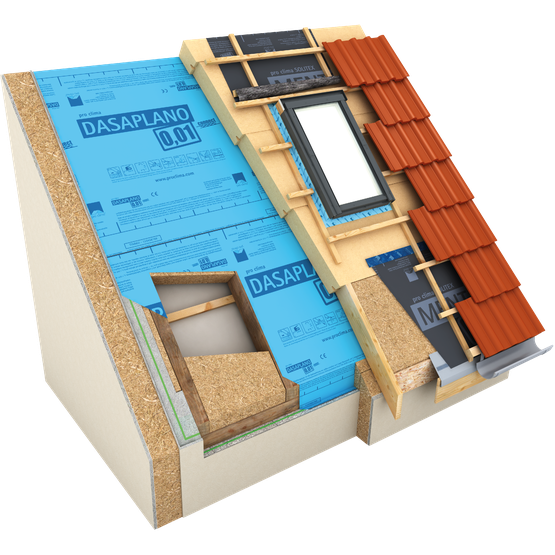

Areas of application

For use as an airtightness membrane that can be subjected to outdoor exposure for roof refurbishment from the outside in the case of full packing of the existing spaces between the rafters with insulation. Installation across the rafters, underneath an additional layer of over-rafter insulation consisting of wood-fibre underlay panels. Please contact Technical Support at pro clima in Germany for assistance with calculating the thickness of the external wood-fibre insulation that is required from a building physics viewpoint.

Technical specs

| Material | |||

| Protective and covering fleece | Polypropylene microfibre | ||

| Functional film | Monolithic polymer mixture | ||

| Self-adhesive strips | Water-resistant SOLID adhesive | ||

| Property | Regulation | Value | Regulation |

| Colour | Light blue | ||

| Surface weight | EN 1849-2 | 145 g/m² ; 0.48 oz/ft² | EN 1849-2 |

| Thickness | EN 1849-2 | 0.50 mm ; 20 mils | EN 1849-2 |

| Water vapour resistance factor µ | EN ISO 12572 | 20 | EN ISO 12572 |

| sd value, humidity-variable | EN ISO 12572 | 0.01 m | EN ISO 12572 |

| g value, humidity-variable | 0.05 MN·s/g | ||

| Vapour permeance, humidity-variable | EN ISO 12572 | 330 perms | EN ISO 12572 |

| Reaction to fire classification | EN 13501-1 | E | EN 13501-1 |

| Outdoor exposure, pitched roofs ≥14°(3:12) | 3 months | ||

| Outdoor exposure for refurbishment betw. 2 insulation layers | 14 days ; 7 days at ≤10 °C (≤50 °F) | ||

| Watertight joints with ‘connect’ adhesive strips or TESCON tape | EN 13859-1 | W1 | EN 13859-1 |

| Roofing underlay category (Germany) | ZVDH-Produktdatenblatt 2024 | USB / UDB | ZVDH-Produktdatenblatt 2024 |

| Suitable as temporary roof covering (Germany) | ZVDH | Yes | ZVDH |

| Watertightness to liquid water | EN 1928 | W1 | EN 1928 |

| Water column | EN ISO 811 | > 2 500 mm ; 8' 2" | EN ISO 811 |

| Airtightness | EN 12114 | Tested | EN 12114 |

| Tensile strength MD/CD | EN 12311-2 | 270 N/5 cm / 200 N/5 cm ; 31 lb/in / 23 lb/in | EN 12311-2 |

| Elongation MD/CD | EN 12311-2 | 55% / 70% | EN 12311-2 |

| Nail tear-resistance MD/CD | EN 12310-1 | 150 N / 150 N | EN 12310-1 |

| Durability after artificial ageing | EN 1297 / EN 1296 | Passed | EN 1297 / EN 1296 |

| Adhesion of 'connect' strips | Above +0 °C ; 32 °F | ||

| Temperature resistance | EN 1109, EN 1296, EN 1297 | Permanent ‑40 °C to 100 °C ; ‑40 °F to 212 °F | EN 1109, EN 1296, EN 1297 |

| Thermal conductivity | 0.04 W/(m·K) ; 0.3 BTU·in/(h·ft²·°F) | ||

| CE labelling | EN 13984 / EN 13859-1 | Yes | EN 13984 / EN 13859-1 |