Reinforced hydrosafe® paper-based vapour control membrane

Advantages

- Excellent protection against damage to structures and mould thanks to humidity-variable diffusion resistance

- Protected winter building sites thanks to hydrosafe® behaviour

- Can be combined with all fibrous insulation materials (including blown-in insulation)

- Ecological solution for sealing of the building envelope

- Excellent values in hazardous substance testing, has been tested according to the ISO 16000 evaluation scheme

Areas of application

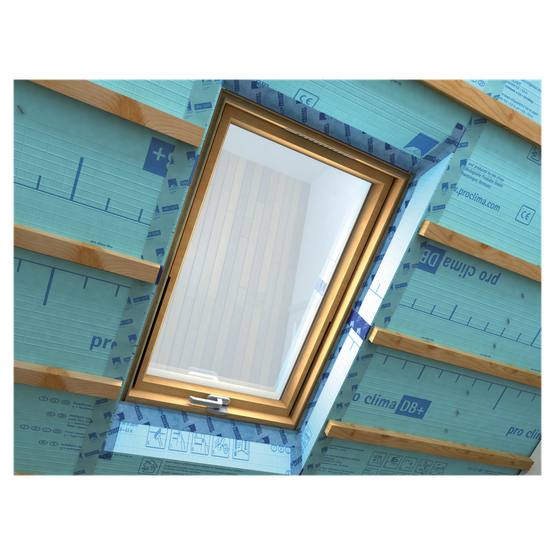

Vapour control (alternate terms: vapour check or retarder) membrane for use on roofs, walls, ceilings and floors in combination with all fibrous insulation materials, including blown-in insulation, on structures that are open or closed to diffusion on the exterior, after appropriate design calculations.

Planning and construction guidelines

Areas of application

The pro clima DB+ vapour control (alternate terms: vapour check or retarder) and airtight membrane can be used as an inner boundary for thermal insulation:

- On roofs, walls, ceilings and floors,

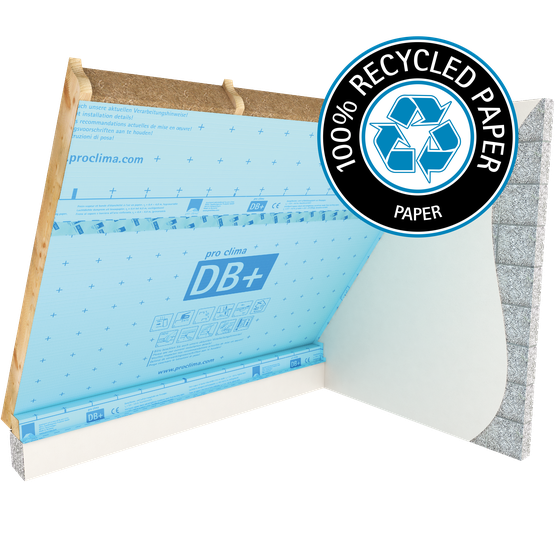

- In the case of refurbishment from the outside:

installation of membranes in the form of ‘troughs’ in the spaces between the rafters, - On residential and commercial buildings that do not have permanently increased levels of indoor humidity,

- On residential buildings or buildings with residential-like use in all rooms such as living rooms, bedrooms, kitchens and bathrooms,

- On structures that are open to diffusion on the exterior and those that are closed to diffusion on the exterior, and

- In the case of demanding requirements relating to indoor air quality

Use of fibrous insulation materials

Moisture must be able to penetrate as far as the vapour control membrane in order for the humidity-variable properties of DB+ to have an impact. Permeable, fibrous insulation materials such as cellulose, flax, hemp, wood fibres, rock or mineral wool etc. ensure that this is the case and are recommended for this reason.

The weight of the insulation material must be supported by suitable interior cladding or cross battens at a maximum separation distance of 65 cm (2’ 2″). If regular tensile loads on adhesive tape bonds are to be expected – for example, due to the weight of the insulation material – when using mat or panel-shaped insulation materials, an additional supporting batten should be fitted over the overlap sealing.

Use of diffusion-open interior cladding

To take full advantage of the potential of humidity-variable vapour control membranes to provide protection against damage to structures, diffusion-open cladding should be installed internally, over the vapour control membrane – e.g. gypsum boards or wooden board cladding. Diffusion-inhibiting layers such as OSB or multi-layer wooden panels hinder drying out to the inside in summer.

Protection of the airtightness layer

The airtightness and windtightness layer is one of the most important functional layers on thermally insulated structures. Particular protection against harmful influences such as UV radiation and mechanical stresses should be provided for this layer. Membranes with a double protective fleece, e.g. INTELLO X, should be used on structures that could be subject to such effects.

The correct construction procedure

The aim of the correct construction procedure is to deliver a fault-free end result for a given project. As a result, the construction procedure is dependent on the relevant interior (e.g. type of structure) and exterior (e.g. time of construction) conditions and on prior planning. As a rule, it should be ensured that the materials used are protected against an unacceptable increase in moisture in adherence with generally recognised engineering practice.

If DB+ is bonded to plasterwork two weeks after plaster has been applied, it should be ensured that no building moisture is trapped in the insulation layer. Alternatively, installation can be carried out before plastering; if moisture is introduced into the building during subsequent construction work, this needs to be removed again in a targeted manner. The increased entry of moisture into insulated or yet-to-be-insulated spaces between the rafters due to air currents and the associated formation of condensation is to be avoided. It is recommended that the vapour control and airtightness layer should be completed directly after the installation of mat or panel-shaped insulation materials.

Blown-in insulation should be inserted immediately after airtight sticking of the membrane. If necessary, carry out this work gradually in steps; this applies particularly to work carried out in winter. Any increased relative humidity is to be removed quickly and systematically by ventilation, particularly in order to avoid mould formation in new buildings.

Increased indoor humidity

The dynamic diffusion resistance of DB+ has been chosen to ensure that there is a reliable vapour-controlling effect even in the case of high indoor humidity for limited periods, which can occur in new buildings as a result of construction work or during short-term increases in relative humidity in bathrooms or kitchens, for example.

Regardless of the type of vapour control membrane used, moisture due to construction work must always be removed from the building structure quickly by ventilation through open windows so that a normal moisture level can be achieved.

Dryers can help to speed up the drying process in wintertime. This helps to avoid permanently high levels of relative humidity and the associated risk of mould formation.

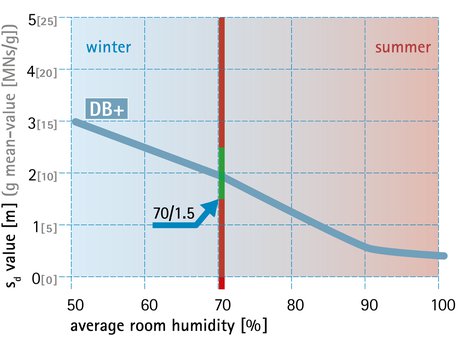

Construction phase: hydrosafe® value (70/1.5 rule)

A vapour control membrane should have a hydrosafe® value of 1.5 m in order to protect structures against dampness even in the case of the increased relative humidity that can be present during construction work.

The hydrosafe® value specifies how well sealed a humidity-variable vapour control membrane still is at an average humidity of 70%. Average humidity of 70% will be present if there is 90% indoor air humidity and 50% humidity in the space between the rafters, for example; this level of indoor air humidity can occur when installing screed or plastering walls.

The requirement that sd should be > 1.5 m and < 2.5 m (g value 7.5 to 12.5 or 1.3 to 2.2 US perms) comes from DIN 68800-2 and is described in further detail by the 70/1.5 rule. DB+ fulfils these requirements reliably.

Quality assurance

Airtightness is the critical factor in protecting the thermal insulation structure against moisture damage. pro clima recommends that the airtightness layer be checked for leaks in a timely manner and that any leaks be located and rectified using a BlowerDoor test, for example, before the interior cladding is installed.

In the case of refurbishment from the outside:

In the case of membrane installation on the exterior, efficient quality assurance can be carried out during the course of construction by means of differential pressure testing with overpressure and artificial fog. As part of this testing, fog is generated inside the building using a fog machine. In this way, the airtightness of detail features can be checked and rectified on the exterior. The membranes must be mechanically secured to a sufficient extent beforehand. For this reason, taped and adhesive joints are to be implemented with particular care. Detailed construction planning – particularly of joints at the eaves and gable ends and the implementation of these joints on roof refurbishment projects – is particularly important. In Germany, this quality assurance during the course of construction is no substitute for final testing of airtightness in accordance with the German Building Energy Act (GebäudeEnergieGesetz, GEG) or the requirements of the German Reconstruction Loan Corporation (KfW) regarding the determination of the air change rate (n50 value).

Proof of durability

The European standard applicable to vapour control membranes (EN 13984) does not currently specify a validation process for testing the behaviour and durability of humidity-variable properties. Accordingly, only vapour control membranes with constant diffusion resistances can be tested in accordance with this European standard. For this reason, the durability of the humidity-variable behaviour of DB+ been demonstrated according to a procedure specified by an independent committee of experts of the German Institute of Construction Engineering (DIBt).

As part of this testing, the vapour control membrane was subjected to accelerated ageing with significantly more demanding conditions (increased temperature and doubled ageing period) as compared with EN 13984. In addition, the permitted deviations of the aged diffusion resistances from the non-aged diffusion resistances have been made significantly more demanding in this evaluation as compared to the European standard. As a result, DB+ has the required proof of durability demanded by DIN 68000-2 for vapour control membranes with humidity-variable diffusion resistance.

Technical support

If you have questions relating to planning and installation, please contact pro clima Technical Support.