Intelligent airtightness

Intelligent

airtightness

Moisture damage to structures and protection measures

- Moisture can enter into building structures in many different ways, and it is impossible to prevent a certain level of moisture loading

- However, if moisture levels are too high, moisture damage to structures can result

- To ensure a structure is protected against moisture damage, the drying reserves possessed by the building component are much more important than the degree of tightness of the vapour control membrane

- Vapour barriers with high diffusion resistances allow for barely any drying from the component to the inside

A high degree of protection against moisture damage to building structures can be achieved with intelligent airtightness.

This is how intelligent airtightness works

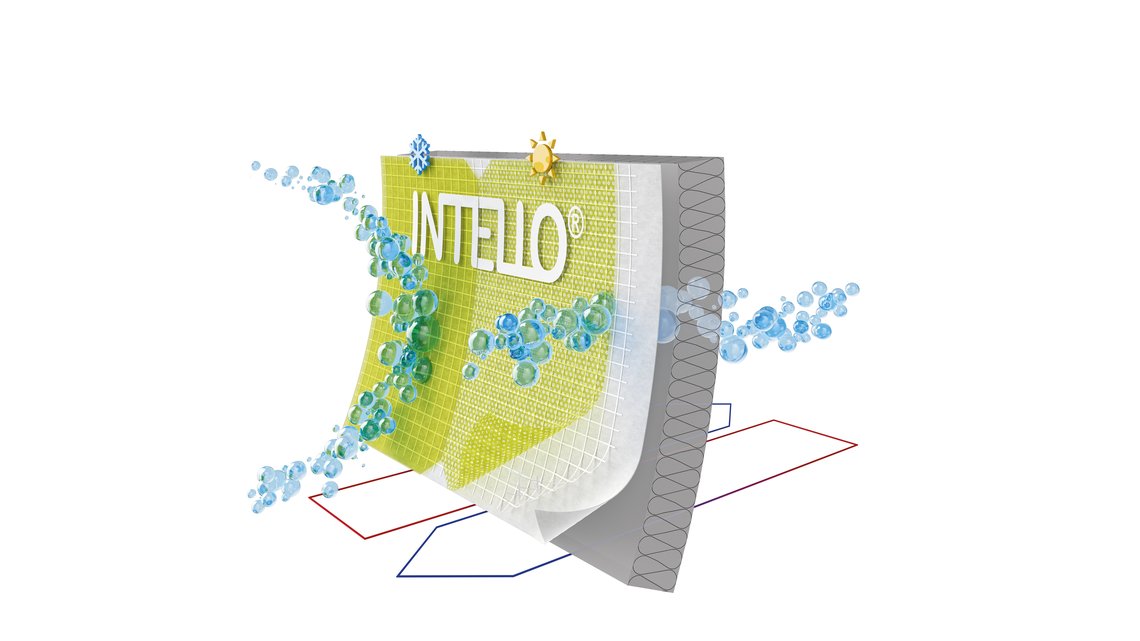

Humidity-variable vapour control (alternate terms: vapour check or retarder) membranes such as INTELLO are particularly reliable. This is because they perform both functions – tightness to protect against moisture, while also extremely open for optimal drying out. In this video, we explain how this works.

Reliable protection with intelligent membranes

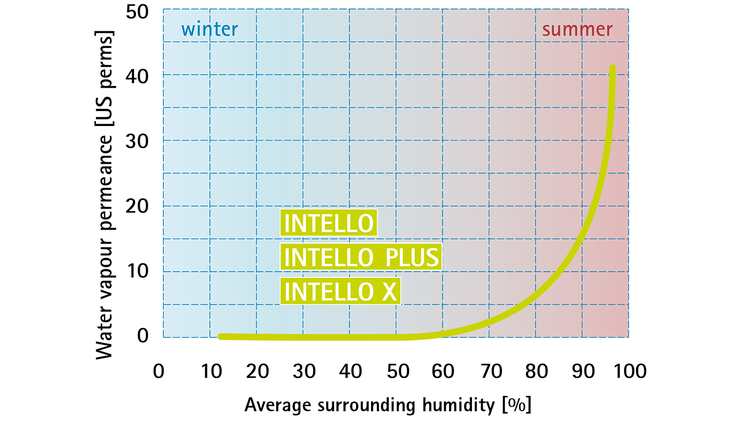

Vapour control membranes with a humidity-variable diffusion resistance provide the best possible protection against condensation water damage to building structures. In winter, they become more impermeable to diffusion and protect the insulation against moisture penetration in an ideal manner. In summer, they can reduce their diffusion resistance very significantly and thus ensure the best possible drying-out conditions.

Basic principle of humidity-variable membranes

Humidity-variable membranes work on the principle of climate-controlled membranes. They react to the surrounding humidity and their diffusion resistance adapts intelligently to the current needs.

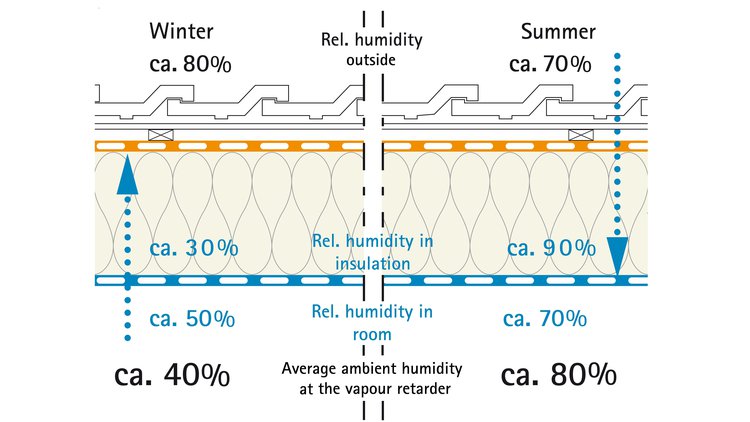

In winter, the average humidity of the air surrounding the vapour control membrane is around 40%. Diffusion takes place from the heated interior to the exterior. In this case, it is beneficial that the vapour control membrane should now have a high resistance in order to protection the structure against condensation formation.

In summer, the average humidity of the air surrounding the vapour control layer is over 80% and the direction of the diffusion is reversed. It is now beneficial that the membrane is open to diffusion to allow moisture to dry out to the inside.

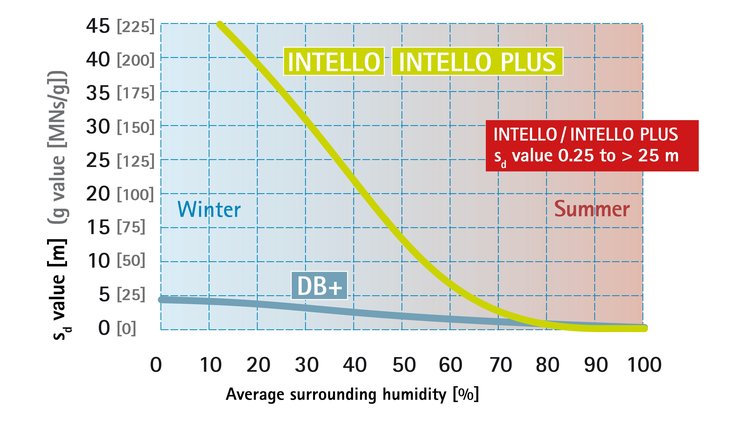

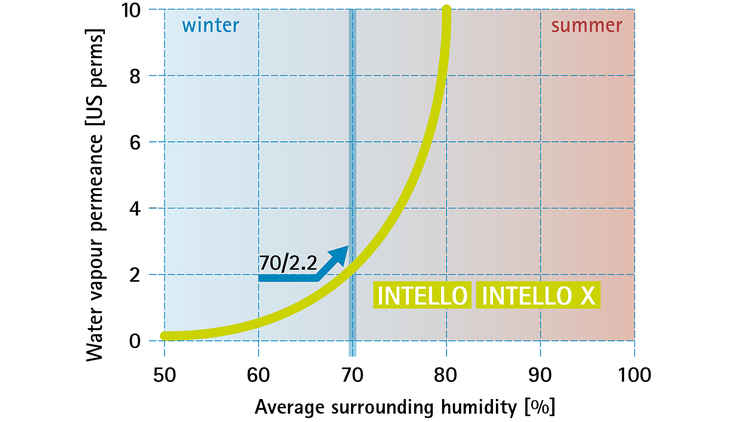

Diffusion resistance as a function of the surrounding humidity

pro clima’s INTELLO, INTELLO PLUS, INTELLO X and DB+ vapour control and airtight membranes fulfil the requirements discussed above. INTELLO, INTELLO PLUS and INTELLO X achieve an sd value of up to >25 m in winter, and of less than 0.25 m in summer. The corresponding values for pro clima DB+ are 4 m in winter and 0.4 m in summer.

The larger the variation in the diffusion resistance between summer and winter, the better the protection will be for the building structure – even in the case of the unanticipated entry of moisture.

To achieve the best possible protection against moisture damage to structures, the drying reserve must be greater than the largest theoretically possible moisture load.

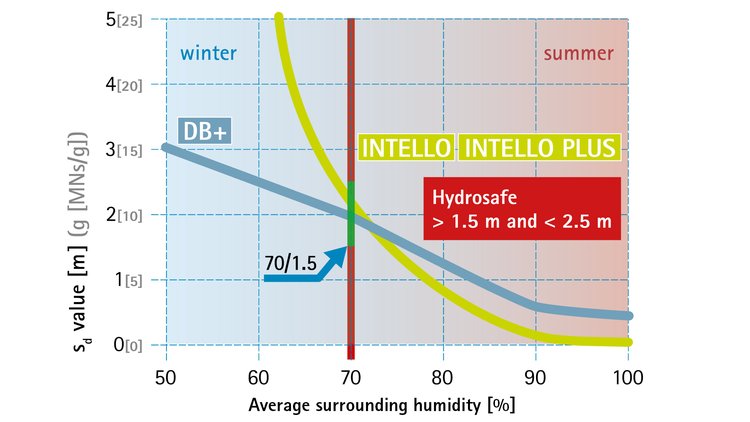

During construction: Hydrosafe value (70/1.5 rule)

A vapour control membrane should have a hydrosafe value of at least 1.5 m in order to protect structures against dampness even in the case of the increased relative humidity that can be present during construction work.

The hydrosafe value specifies how well sealed a humidity-variable vapour control layer still is at an average humidity of 70%. Average humidity of 70% will be present if there is 90% indoor air humidity and 50% humidity in the space between the rafters, for example; this level of indoor air humidity can occur when installing screed or plastering walls.

The requirement that sd > 1.5 m and < 2.5 m is stipulated in the DIN 68800-2 standard and is described in further detail by the so-called 70/1.5 rule.

INTELLO, INTELLO PLUS, INTELLO X and DB+ fulfil these requirements reliably.

As a rule, increased moisture due to construction work should be able to escape the building structure quickly by ventilation through open windows. Dryers can help to speed up the drying process in wintertime. Permanently high levels of relative humidity should be avoided.