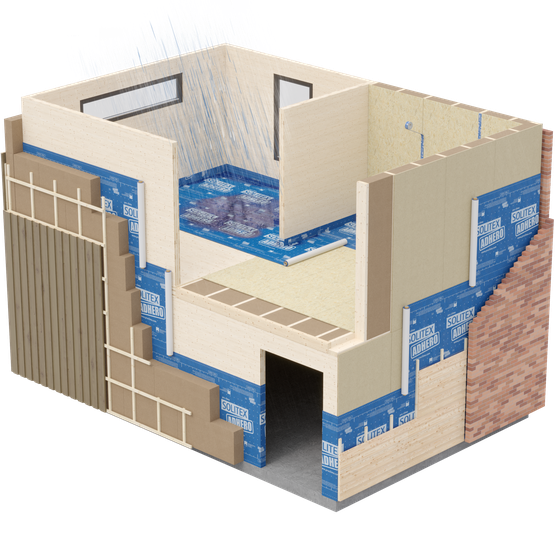

Light-weight full-surface adhesive, diffusion-open airtightness and weathering-protection membrane

Advantages

- Protects the underlying structure: diffusion-open, and maximum protection against driving rain and hail

- 4 weeks of outdoor exposure when protecting floors during construction

- 3 months of outdoor exposure for inclined roofs and walls

- Keeps building structures dry with its pore-free moisture-active functional film

- Easy and reliable installation thanks to the split release film – adheres immediately to subsurfaces that have sufficient stability

- Long-term protection thanks to the high resistance to ageing and heat of the TEEE membrane

- Safe working: anti-slip surface, even in wet conditions

Areas of application

Temporary protection for floors during construction

Thanks to its full-surface adhesion, this membrane provides temporary weathering-protection for intermediate floors on multi-storey CLT (cross-laminated timber) or wooden-frame buildings during the construction period.

Pitched roofs and walls

Allows airtightness to be achieved on wood-based products and mineral subsurfaces – e.g. on the exterior side of unplastered (fair-faced) masonry or concrete building elements with joints. For roofs, it also fulfils the requirements of the Central Association of the German Roofing Trade (ZVDH) for a roofing underlay, and also for a temporary covering for the specified time period.

Installation instructions

General conditions

Temporary protection for floors during construction

SOLITEX ADHERO 1000 is to be installed with the printed side facing the installation technician; it can be installed on stable board substrates (e.g. CLT, OSB, chipboard and plywood sheets). Recesses in the substrate – such as slots, grooves etc. – can lead to increased seepage underneath SOLITEX ADHERO membranes and should be avoided, if possible. To achieve waterproof installation, membranes must be installed with no folds or creases. When installing the membranes, rub them firmly to secure the adhesive bond using a sweeping brush or the PRESSFIX XL tool, for example.

If SOLITEX ADHERO 1000 is to be applied to floor/ceiling elements during the pre-fabrication stage, TESCON VANA must be used to tape the element/membrane joints. Select the tape width so that a width of at least 5 cm (2″) is covered by the tape on both of the elements. Ensure that a width of at least 5 cm (2″) of TESCON VANA covers SOLITEX ADHERO 1000 at joints too. Continue the sealed transition to a height of approx. 10-15 cm (4″ - 6″) at adjacent vertical elements.

SOLITEX ADHERO 1000 can provide temporary weathering-protection for intermediate floors on multi-storey CLT (cross-laminated timber) or wooden-frame buildings during construction for a period of up to 4 weeks.

Water must be drained from the surface of the building structure, e.g. using ADHERO Floor Drain. A short-term build-up depth (max. 24 hours) of 30 mm (1¼″) should not be exceeded.

Bitumen membranes can be welded onto this membrane; the applicable regulations are to be observed.

Pitched roofs and walls

SOLITEX ADHERO 1000 is to be installed with the printed side facing the installation technician; it can be installed on stable subsurfaces (e.g. OSB, chipboard, MDF, plywood sheets, wood-fibre underlay panels, layers of plaster (e.g. gypsum, lime, lime cement, masonry, concrete etc.). The membranes can be installed on walls either vertically or horizontally in an overlapping, waterproof manner. If significant rain loads are expected (e.g. in roof areas or on walls with high loads of driving rain), horizontal waterproof installation is recommended.

To achieve airtight installation, membranes must be installed with no folds or creases. When installing the membranes, rub them firmly to secure the adhesive bond using the PRESSFIX XL tool.

This product can also be used as a temporary covering for up to 3 months to protect inclined roofs with a roof pitch of greater than 14° in accordance with the regulations of the Central Association of the German Roofing Trade (ZVDH). In addition, system products such as the TESCON NAIDECK nail-sealing tape and the KAFLEX / ROFLEX pipe and cable grommets are to be used. The specifications of the applicable national regulations are to be taken into account when carrying out installation and adhesion.

Substrate

Temporary protection for floors during construction

Clean subsurfaces before applying the membranes – remove any protruding elements. Adhesion is not possible on frozen surfaces. There must be no water-repellent substances (e.g. grease or silicone) on surfaces where adhesives are to be applied. Subsurfaces must be sufficiently dry and stable.

It is your responsibility to check the suitability of the subsurface; adhesion tests may be necessary in certain cases.

Pitched roofs and walls

Clean subsurfaces before applying the membranes. Adhesion is not possible on frozen surfaces. There must be no water-repellent substances (e.g. grease or silicone) on materials to be sealed. Subsurfaces must be sufficiently dry and stable.

Sealing and joints are possible with planed and painted wood, hard plastics and metal (e.g. pipes, windows etc.), hard wood-based panels (chipboard, OSB, plywood, MDF and wood-fibre underlay panels) and mineral subsurfaces such as concrete, unplastered masonry or plaster. Concrete or plaster subsurfaces must not be sandy or crumbling.

It is your responsibility to check the suitability of the subsurface; adhesion tests may be necessary in certain cases. Pre-treatment with TESCON PRIMER is required in the case of adhesion to wood-fibre underlay panels or subsurfaces that have insufficient stability.