Vapour control membrane membrane for external insulation and roof refurbishment

Advantages

- Protects building structures against weathering during the construction phase for roof pitches of 10° (2.1:12) and higher

- Water-resistant and waterproof, can be walked on

- Acts as a vapour control and airtightness layer simultaneously

- Excellent values in hazardous substance testing, has been tested according to the ISO 16000 evaluation scheme

Areas of application

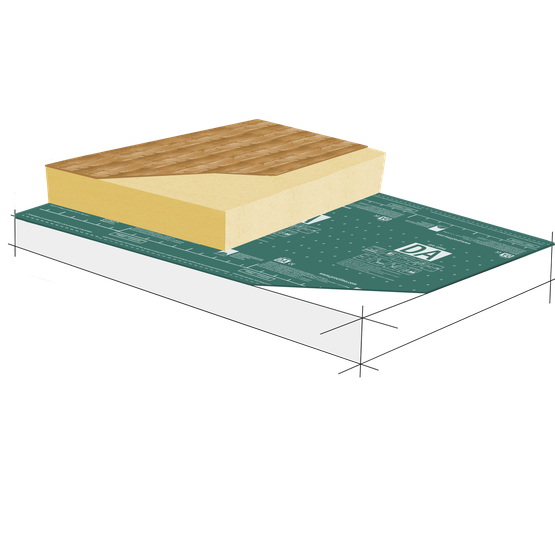

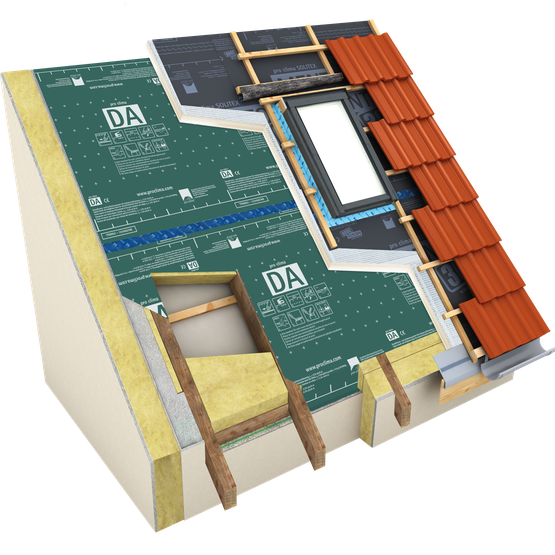

For use as a vapour control (alternate terms: vapour check or retarder) membrane and airtight membrane directly on top of sheathing underneath suitable external roof insulation made of all insulation materials on structures that are open to diffusion on the exterior (roofing underlay with SOLITEX MENTO 3000, for example).

In addition, DA can be installed as an airtight membrane and refurbishment vapour control between two layers of insulation. All fibrous insulation materials can be used for insulation installed between rafters; the external roof insulation must be a foam insulation material (e.g. consisting of PUR, PIR or EPS). Please contact Technical Support at pro clima in Germany for assistance with calculating the thickness of the external foam insulation that is required from a building physics viewpoint. If necessary, the outer sealing layer should be implemented using a diffusion-open roofing underlay membrane (e.g. SOLITEX MENTO 3000).

Installation instructions

General conditions

pro clima DA is to be installed with the printed side facing the installation technician. The membrane is to be installed horizontally (parallel to the eave) in a taut manner. The weight of the insulation material must be supported by the sheathing.

Airtight seals can only be achieved on vapour control (alternate terms: vapour check or retarder) membranes that have been fitted with no folds or creases. Ventilate regularly and systematically to prevent build-up of excessive humidity (e.g. during the construction phase). Occasional, intermittent ventilation is not sufficient to remove large quantities of moisture due to construction work from a building; use a dryer if necessary.

To avoid condensation formation, the thermal insulation should be installed immediately after the airtight installation of DA. This applies particularly to work carried out in winter.

Fastening

- Overlap the membranes by at least 10 cm (⅜″).

- Use fastening staples that are at least 10 mm (⅜″) wide by 8 mm (⁵⁄₁₆″) long to attach the membranes. The membranes can only be fastened in a protected manner in the overlap area. The maximum distance between fasteners is 10 to 15 cm (4″ to 6″).