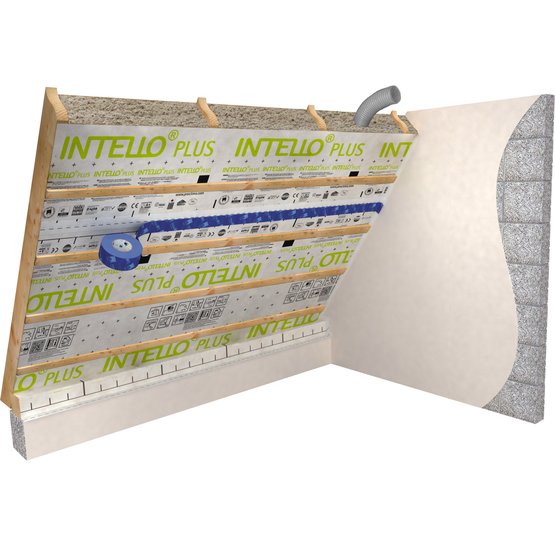

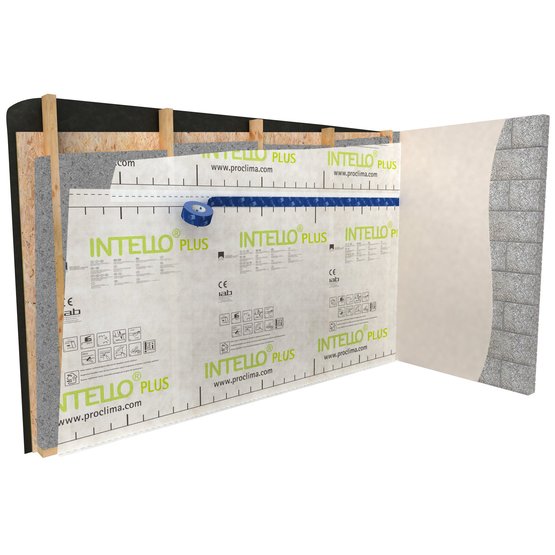

Reinforced hydrosafe® high-performance vapour control membrane, suitable for all fibrous insulation materials

Advantages

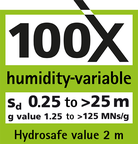

- Best possible protection against moisture damage to structures and mould because this product is humidity-variable with a variation of a factor of over 100

- Can be combined with all fibrous insulation materials (including blown-in insulation)

- Long-term protection: performance tested and certified by independent testing authority (ETA-18/1146)

- Protected winter building sites thanks to hydrosafe® behaviour

- Test winner in April 2012 with the German product-testing foundation ‘Stiftung Warentest’

- Easy to work with: dimensionally stable, no splitting or tear propagation

- Excellent values in hazardous substance testing, has been tested according to the ISO 16000 evaluation scheme

Areas of application

Vapour control (alternate terms: vapour check or retarder) membrane for use on roofs, walls, ceilings and floors on structures that are open or closed to diffusion on the exterior, e.g. flat/pitched roofs and green roofs, after appropriate design calculations have been carried out.

Technical specs

| Material | |||

| Fleece | Polypropylene | ||

| Functional film | Polyethylene copolymer | ||

| Reinforcement | Polypropylene non-woven fabric | ||

| Property | Regulation | Value | Regulation |

| Colour | White‑translucent | ||

| Surface weight | EN 1849-2 | 110 g/m² ; 0.36 oz/ft² | EN 1849-2 |

| Thickness | EN 1849-2 | 0.4 mm ; 16 mils | EN 1849-2 |

| Water vapour resistance factor µ | EN 1931 | 35 000 | EN 1931 |

| sd value | EN 1931 | 14 m | EN 1931 |

| sd value, humidity-variable | EN ISO 12572 | 0.25 ‑ >25 m | EN ISO 12572 |

| g value | 70 MN·s/g | ||

| g value, humidity-variable | EN ISO 12572 | 1.25 ‑ >125 MN·s/g | EN ISO 12572 |

| Vapour permeance | ASTM E96-A | 0.23 perms | ASTM E96-A |

| Vapour permeance, humidity-variable | EN ISO 12572 | < 0.13 ‑ 13 perms | EN ISO 12572 |

| Hydrosafe value (sd) | DIN 68800-2 | 2 m | DIN 68800-2 |

| Surface burning characteristics | ASTM E84 | Class A (Flame Spread 0; Smoke development index 35) | ASTM E84 |

| Reaction to fire classification | EN 13501-1 | E | EN 13501-1 |

| Airtightness | EN 12114 | Tested | EN 12114 |

| Airtightness | ASTM E2178 | ≤ 0.004 cfm/ft² | ASTM E2178 |

| Tensile strength MD/CD | EN 13859-1 (A) | 340 N/5 cm / 220 N/5 cm ; 39 lb/in / 25 lb/in | EN 13859-1 (A) |

| Elongation MD/CD | EN 13859-1 (A) | 15% / 15% | EN 13859-1 (A) |

| Nail tear-resistance MD/CD | EN 13859-1 (B) | 200 N / 200 N ; 45 lb / 45 lb | EN 13859-1 (B) |

| Durability after artificial ageing | ETA-18/1146 | Passed | ETA-18/1146 |

| Temperature resistance | EN 1109, EN 1296, EN 1297 | Permanent ‑40 °C to 80 °C ; ‑40 °F to 176 °F | EN 1109, EN 1296, EN 1297 |

| Thermal conductivity | 0.04 W/(m·K) ; 0.3 BTU·in/(h·ft²·°F) | ||

| Passive House Certification | Passivhaus Institut | phA | Passivhaus Institut |

| CE labelling | ETA-18/1146 | Yes | ETA-18/1146 |

Building projects with INTELLO and INTELLO PLUS

A success story that really rocks!

Although not taken seriously by many when it was first launched, the INTELLO vapour check membrane with humidity-variable diffusion resistance revolutionised construction practice back in the early 2000s. Since then, it has come a long way: an established part of best building practice, the first humidity-variable vapour check membrane with an ETA, certified as fulfilling Passive House standards, and with excellent results in hazardous substance testing. 20 years on from its market launch, it has been fitted on countless projects – ranging from tiny houses right through to multi-storey buildings – on ceilings, roofs and walls to ensure the integrity of the airtightness layer.